-edible zone-

Vertical Tracking Angle (VTA) describes the angle between a line,

from cantilever pivot to stylus contact area, and the record surface.

While this angle is manufactured into the cartridge, VTA will require

setting when installing the phono cartridge to a tonearm. On a pivoting

tonearm, such as the Thorens TP16 in use below, a final VTA setting may

be arrived at by raising or lowering the tonearm at it's base mounting.

Raising the entire tonearm will increase VTA, lowering will decrease VTA.

Conversely, raising or lowering the vertical position of the stylus as

it rides the groove will have the same effect as raising or lowering at

the pivot end. Different thickness records or platter mats can alter VTA.

And... it is presumed you have no plans to add shims between cartridge

and headshell. So we focus on making the vta/sra adjustment by

moving the base mount at the axis end up or down.

Arriving at the correct VTA may or may not seem to be a simple

matter. In a perfect world, where every record is perfectly flat and is

cut on a machine that conforms to the same exact VTA standard, and every

record is exactly the same thickness. VTA would only have to be set

once. I don't know about your world, but in mine records come in varying

thickness' and are often slightly warped. To make matters worse, some

records have had their masters cut at a slightly different Vertical

Tracking Angle.

Setting VTA on a Thorens TD160 with TP16 tonearm.

This

procedure makes the assumption that all other tonearm adjustments have

been made previously. VTA should be in the ball park when making the

other tonearm alignments. If VTA has been altered by a large amount, it

could prove useful to double check your overhang setting with a

protractor just to be certain that this has not been altered. Small

amounts will be of no consequence. Another cautionary note; changing VTA

by large amounts to accommodate taller platter mats will also require a

similar height adjustment for the standard cue bar of the TP16 and TP11

tonearms. See photo #6 at bottom.

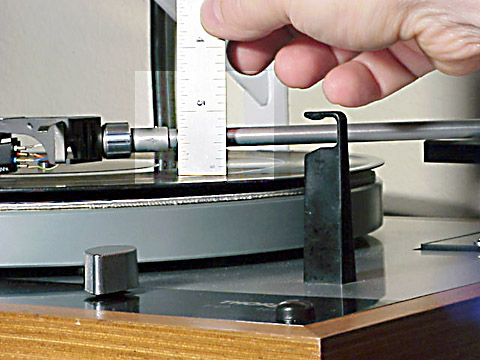

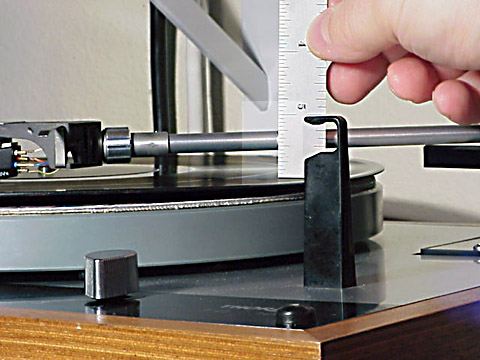

A practical approach, for those

who wish to set VTA only once, is to choose the median thickness record

with a median amount of warp and use this as your listening test mule

for setting VTA by eye and ear. Initial setting will be to get the

bottom edge of the arm tube closely parallel to the record surface. As

seen in photos 1 and 2, with stylus resting stationary in the record

groove, arm tube is the same 7/16 inches off the record surface measured

at two points with some distance between them along the arm tube. This

can be a starting point for the adjustments by ear. ( BTW, your distance

does not have to be 7/16. This will vary according to cartridge height

and mounting shims, etc. It just needs to be the same distance measured

from two points.)

For adjustment by ear I like to sacrifice a

favored album that is typical of the music most listened to. As noted

above, this record will be of a median thickness from the record

collection. I will listen to various tracks of this album repeatedly as

adjustments are made. Naturally, this will induce accelerated wear into

the record. This is one reason I have multiple copies of favorite

albums. Adjustment increments can be precisely made using methods

illustrated in photos 3, 4 and 5. When searching for the "ballpark" I

will make incremental adjustments of .02 inches. When I think my sound

is in the ballpark and needs a closer fine tuning, this increment is

reduced to .005 inches. All this is determined in the stack-up of feeler

gages shown below and a given setting can be repeated at will. Take

notes of your feeler gage stack-up values that work and those that

don't.

What am I listening for...? The fullest, most alive sound.

In general, when VTA is too great (arm base too high) the sound will go

hard and metallic, when too small (arm base too low) sound will go

lifeless and lack detail.

1)

2)

3)

A measured stack-up of feeler gages fills the gap between the arm board and the bottom of the anti-skate fixture at the tonearm base. One hand holds the gages while the other hand tightens the screw. There is a certain element of 'feel' involved in terms of a tight or loose fit. I want to feel a bit of drag on the stack-up of feeler gages as I push them into this gap.

4)

Two allen set screws hold the tonearm in place. The first set screw is shown in photo 4. The next set screw is 90 degrees to the back. Size of allen wrench is 2mm. Remember to park the tonearm in the rest before your start this. Once the screws are loose, the entire tonearm may be raised or lowered. I prefer to hold onto the upper portion of the gimbal frame to lift and lower the tonearm. Place your stack-up of feeler gages in the gap and then lower the tonearm onto it. Caution; don't attempt to remove the tonearm or you may damage the fragile tonearm wires which are soldered to a ter minal inside the box. There is no recommended torque value for the set screws so I use the small end of the wrench to tighten the screw (less leverage). This keeps me from over-tightening.

5)

Here is the gap after setting. The actual surfaces that register this

fit are narrow but give the most repeatable location for this adjustment

on this tonearm.* I like to record my gap distances for a given

turntable mat that I happen to be trying out. This way I can easily

return the tonearm height to a previous setting.

*other tonearms

may have a different, more suitable location for these measurements.

6)

If you raise or lower the tonearm by very much, it will also be necessary to adjust the height of your cue bar. A single set screw holds it to the shaft. Release the set screw and slide the bar up or down. The bar should clear the arm tube when parked but hold the stylus above the record surface by a comfortable height margin. This height margin may be set according to your preference.