-edible zone-

-- The TD124 (sn#2729) was in good order. The next step was to slip

it into another plinth. Something new.

The new plinth: Slate as a

base material back in 2007 was popular and, thanks to a joint effort

between myself and Jonathan Weiss of Oswald's Mill Audio, it became

available. His resources, my cad drawings. The decision was made to

build a solid plinth out of slate. The solution would not be limited to

just a plinth, however. A dedicated turntable stand was also on the

drawing board.

About Slate: It is a metamorphic rock. A

shale-type sedimentary rock. It does not have the hard crystalline

structure of most other rocks, like granite. A soft rock that can be

easily split along its layer lines using hand tools, or it can be carved

into shape. The most common use is for high quality, long lasting

roofing tiles in residential applications. Another use is for counter

tops within the home. Yet another application is the ultra-flat bed

surface underneath the felt fabric in high quality billiard and pool

tables. I don't know who it was that first thought to make a turntable

plinth out of slate.

In that time (circa 2007) it was a popular

notion that heavy thick slate could absorb and dampen the idler's

drive-train vibes thus helping to reduce rumble levels at the

stylus/groove interface. A quieter background to its music being the

goal. More on that lower down.

-- Jonathan Weiss:

To get the slate I worked with Jonathan

Weiss of "Oswald's Mill" in Pennsylvania. There's a slate quarry near

there. From the quarry he takes large milled slabs of slate to another

nearby facility where it gets cut to dimension by means of a cnc

abrasive water-jet machine. This is where I helped. Based on

measurements taken from my TD124, I produced three dimensional cad files

in ".dxf" format for the water-jet programmer to develop his cut paths.

I also provided some hard templates as a reference check to make sure

the cut-outs fit the turntable without interference of fit anywhere. I

also produced a 3D cad file for the armboard and its three fastener

holes to be made also from slate.

The plinth design:

*

(hint:

click thumbnail for full image)

(hint:

click thumbnail for full image)

-- Above are original concept sketch renders in 3d to show

interior/exterior shape. The design provides a 2 inch border all around

the chassis and uses two stacked slabs, 2 inches thick, and then 3 slate

blocks for feet. Gravity holds it all together. No threaded inserts. No

dowel pins.

The first parts:

The textured top surface we

saw on the first parts is called a "cleft surface". It is done by hand

where the slate guy hand chisels the rock parallel to the layered

structure. It was beautifully done. They weren't supposed to do that.

Our plinths needed to have smooth flat faces to maximize

chassis-to-slate contact. Now it was up to Jonathan and I to lap the

faces flat on our prototype slate plinths. I'm quite sure he's better at

working slate than myself. I never really got into working slate. Maybe

I'm not that into it because it is heavy and fragile. Easy to fracture

on impact. A job to tote around. Think hand truck to move it and wood

crate to protect it for ship and storage. And its cool.

After we

had finished parts there was another discrepancy. The inner contour that

fit my early model TD124 had some clearance issues in the vicinity

beneath the armboard support on Jonathan's somewhat later TD124 (also a

mk 1). The discrepancy was about a casting design change in the area

adjacent, above and beneath the armboard. Thorens made changes to their

castings at the armboard platform where it transitions into the chassis.

The early ones have a fairly sharp corner right there. Thorens beveled

that corner to add strength. And then a gusset was applied beneath

centrally.

The casting update was a correction made to help keep

it from getting bent by the people handling it. On those early ones you

could pick the thing up and in so doing bend the armboard support. In

the years since discovering this I have found several examples of the

TD124 pre-bevel/gusset that show a bend right there. The later casting

design - with the gusset and bevel- don't seem to have the problem.

Below are some detail views from the TD124 project pages at The

Analog Dept. to help illustrate the difference that came with the

casting change.

* sn27520

detail photo at bevel

sn27520

detail photo at bevel

* sn27520

another view of the bevel

sn27520

another view of the bevel

*

sn2128 detail photo underneath: no gussett

*![]() sn2078 detail photo from above: no bevel

sn2078 detail photo from above: no bevel

* (click thumbnail for full image)

(click thumbnail for full image)

-- Both casting versions were mk1 but mine was an early model from

circa 1958/9 with a 4 digit serial number (2729) while his was later

with a 5 digit serial number. The casting foundry was Inca. Obviously

the Thorens design staff at Ste. Croix needed to make changes to their

casting over the years. And this wasn't the only casting change that

they made. More on that later in another section of the TD124 dept.

Anyway the crew at the water-jet shop made adjustments to their

program. For my prototype sample I used a pneumatic burr grinder to dig

a trench to clear the gusset on the two other TD124's I bought later.

One of which I still have....sn 13943.

-- The Look:

*

-- Above photo: Revised TD124 chassis with bevel at armboard. You can see the cleft top surface on Jonathan's first slate plinth sample. Note round corners and beveled edges in the slate. Texture seen in the flat side surfaces is like exotic hardwood. Beautiful, I thought. My imaginings produce a scene of the guy in the slate shop saying its far better looking with the cleft work. (it is) But that's just the TV in my head. The cleft surface had to be boarded / lapped smooth like was done on the side faces.

*

-- Above photo: Chassis doesn't lie flat everywhere. Not yet, but just look at it... Photos by Cynthia Van Elk. For more of Jonathan's slate designs link here.

__________________________________________________________horizontal rule

-- Then there's what I did

I worked mine somewhat different. I

left the corners square and at first decided to insert 1-inch thick

slate blocks to separate the top and bottom layers. My thinking at the

time was that even the two inch thickness of the single layer was more

than sufficient to enhance damping of the TD124 drive train. So here I

was; never worked with the material before and yet I had an opinion.

caution: idiot off leash

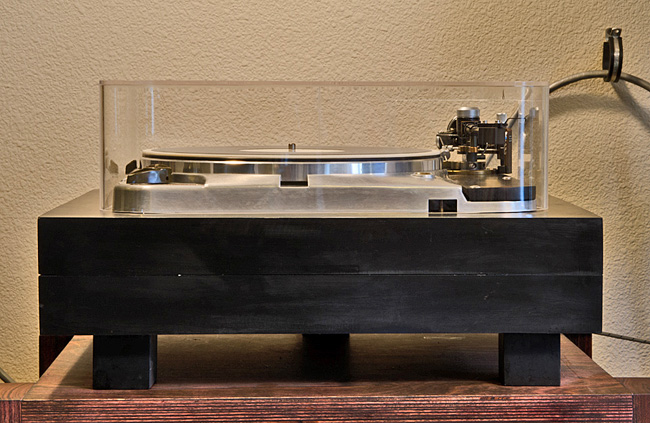

*

-- Up on the stand. 52 lbs of slate under the 124 chassis. Each slab is 2 inches thick. Between the two slabs are three 2 x 2 x 1-inch blocks of solid slate acting as support spacers. For the three feet more solid slate is used in a 2 x 2 x 2 inch cube configuration.

*

--#At a later date I was to go ahead and stack the upper and lower

layers together. I also did some surface lapping to get these two upper

and lower layers to seat. When complete the seating was good enough to

create an effective vacuum seal between them. It was like they were

stuck together. Sonics-wise it made an audible difference. Jonathan was

right. Two 2-inch layers intimately seated one on top the other gave a

quieter background behind the music than block-spaced apart as I

initially had it.

Metal fasteners: Mounting studs, soft pvc

grommets*, thick aluminum washers and thumbnuts at the usual four

places. For stud material I used brass-threaded-rod. Btw, thread size is

m5 x 0.8mm. Thorens originally supplied these units with a soft steel

mounting stud. I decided to use the even softer brass rod. See photos

just below. The adjusters ,without rubber mushrooms, were screwed down

into light contact with the slate after it was established that the

TD124 chassis was making full contact against the slate. Unless I chose

to not include the adjusters, as is seen in the above later date photo.

*

(hint: click thumbnail for full image)

(hint: click thumbnail for full image)

-- Listening Impressions

The goal here is to make a comparison

between the two plinth types for signal to noise ratio (aka rumble) and

then afterward to take note of the sonic qualities subjectively observed

while holding the same TD124 unit.

Since first writing this

article in 2007 I have produced spectrum charts while testing different

bearing thrust pads on my SP10 mkII. I might have used the setup to do

the same here. But not when I originally wrote this article. The SP10

mkII business came a couple of years later. I didn't have the digital

recorder at that time. For the SP10 mkII I used an Alesis ML-9600

digital recorder to record the silent groove track on the test record

from Hi-Fi News and Record Review; HFN-001. I used the ML-9600 to burn a

CD-R of the track -- then in my desktop computer "Audacity" software was

used to analyze the recording of that track by means of a spectrum plot

that showed frequency and amplitude of the un-modulated groove. The

amplitude is reported in decibels that go deep negative. The frequency

is reported in Hz (cycles per second) from zero hz upward. The process

provides a useful and repeatable reference for anyone modifying their

turntable. Anyway that SP10 mkII is going to produce a quieter plot than

will any TD124...but that's beyond the scope of this article. We just

want to know if the slate actually did improve the signal to noise ratio

(rumble) of the Thorens.

We can reference to published specs

coming from Thorens themselves for Signal to Noise Ratio (rumble) as

well as wow/flutter. These values were reported in a controlled

environment at the workshops in Ste. Croix back in 1959 showing an

un-weighted rumble figure of -36db. (decibels) That's a useful

reference. What we need to know is -- does the use of the slate plinth

produce a quieter rumble figure? Can't answer that. I haven't yet tested

the TD124 for rumble. I just listened to various familiar records and

then subjectively made note if I thought the background silence was

better in one plinth or the other. Usually you can tell by the amount of

fine musical detail one setup produces in comparison to the other. You

can also hear it in the lead-in groove and also the un-modulated groove

between tracks of your favorite Lps. Otherwise rumble tends to mask the

finer details and that sense of airy-ness within some recordings. The

more rumble, the lesser fine detail. Listen for it, the differences

become apparent.

I can't say that the slate works any miracles

here. In terms of open box with mushrooms versus heavy slate without

mushrooms the comparison is very close to my ear. Maybe the slate does

seem to have a bit less rumble. I hear it in the lead-in groove and

between tracks. And I hear the musical details of records I'm familiar

with. That much tells me that this very thick slate is indeed good. If

the comparison were open box without mushrooms versus slate without

mushrooms the comparison would be more fair and the slate would show a

more apparent advantage. I'm confident of that.

Impressions

updated circa 2018 - 2021.

I think until I can get a signal to

noise chart on this I will refrain from going into detailed accounts of

my listening experiences while in slate versus in the oem plinth with

mushrooms. What I can say is that either plinth method can produce a

very good listening experience. I can also say that in either of those

build methods that driving rhythm that we treasure our idler driven

turntables for could be heard to full effect. The slate doesn't seem to

get in the way of that. It's good, actually.

Fwiw, I've also

listened to the TD124 in a variety of different baltic birch plinths;

both heavy in build and light in build. With or without mushrooms, those

were good as well. Were there differences heard in terms of rumble being

lesser or greater? Yes. Mushrooms help to produce a quieter background

noise levels (rumble) while in the wood plinths I've tried so far..

-- Associated equipment:

-phono stage: Wright WPP100C

-phono

stage: within the CAP 151 integrated amp.

-Tonearms: Expressimo RB250

(modded) and a Graham 2.2

-Cartridges: Shelter 501-II, Ortofon

Jubilee, Denon DL-103R in a Ebony body by Uwe.

-Classe' CAP 151

integrated amp

-NHT 2.9 4-way tower speakers

-more system details:

link