-edible zone-

--#Review: Boston Audio Mat 2

- Date: 11/24/2013 with edits 6/18/2017

- Author: Steve Clarke

- Model: BA Mat 2

- Category: Turntable platter mat

- Suggested Retail Price: $279 (includes shipping)

- Description: Solid machined carbon graphite platter mat

- Manufacturer url: https://www.boston-audio.com

- Manufacturer: Boston Audio Design

- Made in USA

- Distribution: refer to BA website for dealer location near you: link: https://www.boston-audio/dealers.html (or buy direct)

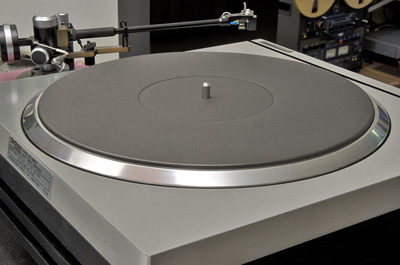

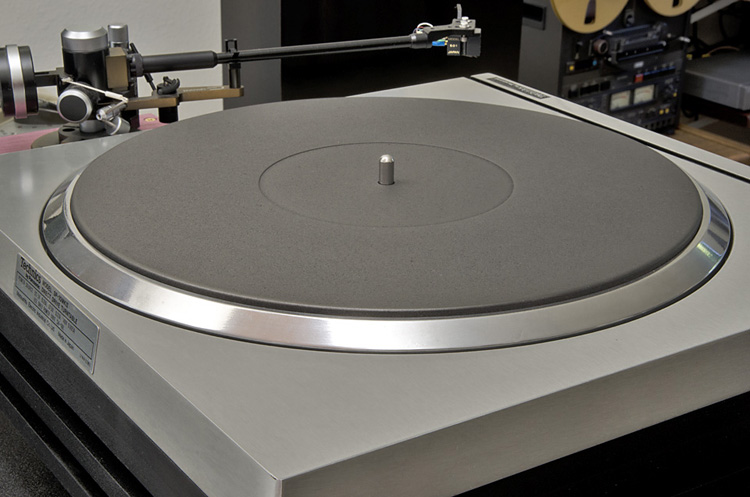

Photos of the mat in use during this review:

*

Above photo: BA Mat 2 on author's Technics SP10 mk 2

It started with a question; "which mat might be best for this very

good sounding record player?" Is any mat other than the standard issue

rubber mat preferable?

At this moment in time we live in the age

of the internet. On the internet one can query any of a few dominant

search engines to provide a list of discussions and articles on any

topic. Most of it is available freely. Some of it is not free.

So,....... restricting myself to the free info, I queried Google on

platter mats for the SP10 mkII and came up with some useful suggestions.

To summarize some of the serious contenders, I can list a few popular

mat options for the SP10 mk2 that came to light during my search.

- SAEC SS 300 solid mat (Japan).

- Boston Audio Mat 2

- OMA graphite Mat (USA)

- "Vintage" Micro Seiki solid copper mat (Japan, 2nd hand)

- The original Technics mat for this player (typically, every used sp10 mkII that you can buy will, likely, come with one.

- Herbies Audio Lab: Way Excellent II - 5mm (USA)

From the above list, and from having read several reviews on Boston

Audio turntable mats, I decided on a BA MAT 2 as my first choice. A

hunch....but there are many who will support the choice. And this is

based on their own experience with Boston Audio turntable mats. So I

simply surfed the web over to Boston Audio Design's site and asked the

proprietor there (Austin Jackson) if I could buy a mat. This mat is not

free. I had to pay. So would you. But there is a 30-day trial period as

part of the deal. And shipping was included within the asking price.

Ordering: By email direct from Boston Audio Design. Payment was

convenient. I used Paypal. Delivery was timely. Austin sent the mat via

USPS 2nd Day air. Receiving: The mat arrived intact in a well packed

box. Double boxed actually. It also comes with a letter sized data

sheet.

Putting to use: All I had to do was remove the Boston

Audio Mat 2 from its shipping container, remove the Technics rubber mat

from the player and plop the new BA Mat 2 down over the spindle pin.

Then, I thought, it was ready to play records. Or was it.

Observations: The OEM Technics mat is

thick. Five mm thick as a matter of fact. (.197 inches measured with

digital caliper) So is the Boston Audio Mat 2. (5mm) The OEM Technics

mat is made from some unidentified compound of firm rubber. Firm yet

supple. Even after 34 years in the atmosphere, my sample remains supple

and perfectly fit for use. The Boston Audio Design Mat 2 is machined

from solid graphite and displays no flexibility. It is a hard mat.

The BA mat 2 fits down over the spindle and into the pocket of the

SP10 platter like it belongs there. On my sample The spindle hole on the

BA mat is a bit oversize. Enough so that some care might be taken to

ensure that the mat is well centered over the spindle pin. Otherwise

there is some evidence of eccentric run-out between mat and platter as

the platter turns. This is seen only if you are looking for it, but if

your are the evidence is there.

The BA Mat 2 is machined (lathe

turned) from solid carbon graphite (BA is protective about the exact

composition of the graphite they use). It is a solid, rigid piece that

does not flex with normal hand pressure. Nor does it seem to flex under

its own weight. It is a stiff piece. Place the BA mat 2 on this platter

and one wonders if there is adequate traction between the aluminum

platter of the SP10 and the mat. For good reason. There is no

traction.

The SP10 mkII motor produces one heck of a lot of

torque when it starts and stops spinning its platter. It is presumed

that the torque is also delivered when it makes speed corrections during

the course of playback. With the oem mat in place, hold a record brush

on a spinning record and watch the Technics' strobe. The strobe

indicates that platter does not slow down from this application of

external force onto it. Neither the record or mat. However, do this with

the BA Mat 2 and the -record- appears to come to a stop while the

platter continues to spin. At first I could not tell if it was the

record slipping against the BA Mat 2.....or if it was the BA Mat 2

slipping against the sp10 platter. This much I was able to sort out by

what I did next.

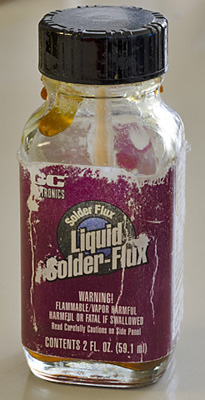

The stuff I used to "stick" the mat to the

platter is resin of a type that comes from trees. Liquid solder flux.

You can find a very similar product under the name "Pine Tar". Also

known as pitch. Tree pitch. It is a gummy, sticky residue. Organic

stuff. Park your car beneath a pine tree and come back later to find

tree pitch drops on your nice shiny paint job. Sticks like glue. Heck,

tree pitch is even used as an ingredient in some glues. But is it too

sticky?

* Photo: rosin solder flux

Photo: rosin solder flux

Firstly, I removed the brand new BA Mat 2 from its recess

within the SP10 platter. A beautiful piece of machining, the SP10 mkII

platter. Then, using the brush applicator of the liquid solder flux jar,

I applied a circular array of small dots of pitch to the Technics'

platter surface. I did so sparingly. Thin dabs. Not very much and just a

1/2 dozen light spots of pitch. Then I replaced the BA Mat 2 into the

sp10 platter. And I allowed the resin a few minutes to firm up.

Afterward, the record would not slow when holding a cleaning brush

against it while spinning on the platter. This told me it had been the

BA Mat 2 that was slipping against the SP10 platter.

The next

day I was able to remove the Mat 2 from the SP10. This means that the

rosin isn't dangerously sticky. What I found were areas of residue

spots, nickel sized, sticking to both the inner platter surface and also

to the bottom mat surface. It is possible to clean this off, but I want

to leave it there to provide traction between platter and mat. No

apparent damage done. Problem solved. Others have volunteered their

solutions to this problem. Some suggested putting down an array of

transparent tape onto the inside surface of the platter. Then the mat 2

will find some traction between itself and the top non-adhesive

substrate of the tape. Seems like a good suggestion to me.

Another observation: Some records may have a type of warp that will not

allow any type of grip between the mat surface and record. A dish warp

being the worst case. Warped records like this will have little traction

against the mat and may lose traction during playback.* My solution to

this problem is to simply not play such records on the mat. Others may

solve the problem with a a record clamp that goes over the spindle pin

in combination with a spacer puck that fits over the spindle but beneath

the record, thus curving the record into contact with the outer rim of

the mat. Still another solution would be a rim weight.

*. It should be stated that any 'hard' mat will exhibit this behavior; no traction (slippage) between mat and record.

Listening:

(11-24-2013)

The comparison between the oem rubber mat and the BA Mat 2 right

away reveals some sonic differences. It was quite obvious (with the BA

Mat 2) that upper frequency notes appeared cleaner and with sharper

articulation. More air. More float. More sustain. Longer decay. Mahler

No. 5. Haitink / Amsterdam Concertgebouw on Philips. Opening trumpet

solo and the combined brass instruments that carry the piece forward and

into the symphony was and were clean and relaxed. No brass blare. No

haze. No perceivable distortions. Just clean massed brass instruments in

nice focus. With the oem rubber mat in comparison the same passages has

a slight glare. Like peering through a lens at a subject that is

back-lit by the sun and with a slight solar flare blocking parts of the

view. In direct comparison the BA Mat 2 appears to have cleaned the lens

for this part of it.

Led Zeppelin II (Classic Records 180g).

Whole 'Lotta Love; It may seem that one normally wouldn't expect to hear

lots of fine inner detail in hard rock recordings. But there are - in

fact- tons of fine detail to be reproduced in these recordings. That is

when your record playback system is capable of doing so. On this first

track of side 1 there are numerous fine details floating within the

driving atmosphere of it. Firstly, I noticed how the cymbals were

reproduced with excellent tone and timber of the spun bell bronze

they're made from. Realistic. But it did not require an analytical ear

to notice how long the sustain and decay of each cymbal hit was.... The

initial strike; stick against metal. The splash, ripple, shimmer and

ring. Like floating and flying in the space between and above the

speakers. While these artifacts are prominent and obvious in the

recording, it was also obvious that with the mat 2 the above noted

musical artifacts were improved by a remarkable amount.

Then,

toward the end of the piece, the driving rhythm notes appeared to be

accompanied by soft musical reply to each phrase. Not heard with such

clarity before this. It is an inner detail. Keep in mind that the SP10

mkII is very capable of reproducing lots and lots of detail from within

the record groove. But now, with the Mat 2, there is more detail to be

enjoyed. Not analytical. Its just there in the space before me.

Driving rhythm. Musical energy. That sense of flow........what are the

effects of the Mat 2 on these? Nothing deleterious that I can tell. I

may have been concerned about this when I saw the mat 2 slipping against

the sp10 platter. But that thought is put to rest. And what I hear is

foot tapping, dance inducing rock and roll drama. Good stuff. For the

SP10 mkII, I like this mat. Recommended provided you can live with a

hard mat for the above previously noted reservations.

(6-18-2014)

Added listening notes:

Now that I've had this BA Mat 2 for half a

year I can say that I still continue to use it on the SP10 mkII. I've

found it acceptable to live with the mats short-comings (poor traction)

as well as the mats sonic benefits. The primary and most noticed

difference between the BA Mat2 and the oem standard mat is in the upper

frequency region where an obvious sense of added clarity exists. The

other frequencies are not adversely affected. Nor can I say that I hear

any overt differences there. I should also note, again, that there is no

change in VTA/SRA when changing the oem mat with the BA Mat 2. Both mats

are the same thickness.

I can also note that even though I've

been skeptical about the lack of traction between record and this hard

mat, there does not seem to be any absence of visceral energy when such

should be present. Not that I'd notice subjectively.