-edible zone-

Article expanded and updated 09/16/2022,

edits with

contribution from C.Brady at Teres Audio 09/27/2022

Teres Audio

had been in operation for some time. They began with the Maxon A-max

110189 DC motor and later the RE-MAX 226754 motor in the Signature 3 and

the expensive RE25 (M030958) 'Reference motor' with great results.

However, in 2004 troubles arose. Maxon made a change to their precious

metal (platinum) brush motors that rendered them unusable for this

application.

The motors functioned flawlessly for a few months

and then the speed became very erratic. According to Maxon the problem

surfaced because the motors were being operated at low speed, rather

than nearer to their design speed. Teres worked with Maxon to find a

solution and for a short time used a custom, special order gold brush

motor. With the arrival of the Verus motor Teres discontinued the

Signature and Reference motors. It is not known which specific Maxon

models suffer from the brush problems or if the issues have changed over

time. Given this history there is good reason to believe that current

Maxon motors would likely be unsatisfactory for use as a turntable

motor.

So.....if you're still using an older A-max 110189 (pre

2004) it can be maintained by making sure that all the bushings, upper

and inner, receive fresh lube periodically.

Presently the only

motor option available from Teres Audio is their Verus Direct-Coupled

motor and controller. It is a rim drive design that I have reviewed

elsewhere within this site and I can attest that it does work very well

and is simple to set up with your Teres turntable.

About this

motor that we have been using-- the older version A-Max 110189: It is DC

powered and has a commutator -- complete with precious metal brushes.

Platinum, I am told. The platinum brushes are covered with grease and by

this design don't give off sparking and noise as do the more ordinary

brushed motors I can remember from my long ago youth -- slot car racing.

These are certainly not exactly that, though with some similarities of

operation in that to increase voltage to the motor will increase its

rpm. I can't think of too many turntables that have at one time used

brushed motors, apart from Teres, Galibier and Red Point In general,

turntable motors tend not to use commutator brushes. Yet, and as I

recall from my experiences with my Teres model 145 the listen was good.

That turntable had lots of inner vision, space and resolution of detail.

The older A-max 110189 does in fact run smooth and quiet when it's

healthy.

*

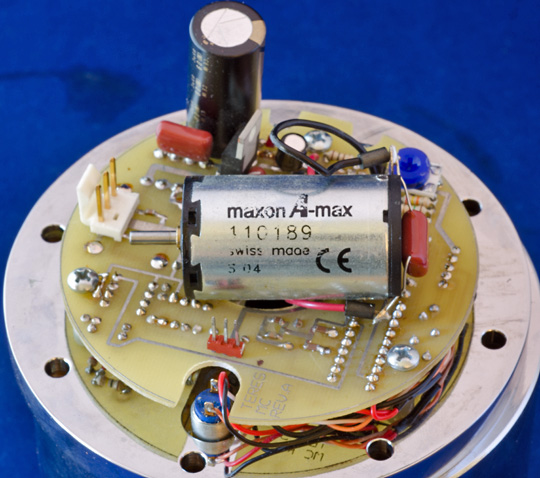

Last month (August 2022) there was a Teres that showed up in my tiny little world. It was one of the first ones where buyers bought individual pieces of the kit to build their own. It had been in storage for a number of years and the owner wanted to see what it might take to get it operational. I was interested and agreed to take a look-see. The most crucial part turned out to be the motor: a DC powered Maxon A-max 110189 with Platinum brushes. It had a loud knock..

*

Above photo:the motor knocks....but the Manfred - MC Rev A -

controller works fine.

Still in its pod, not plugged in, pulley

was off, so I just gave the motor shaft a spin between thumb and

forefinger. Doing this, I noticed a noisy rattle between shaft and

bushings --- the shaft had some perceivable bushing slop and there was

some end play. Dry bushings. From experience with my own Teres I had

found it simple to get lube into the upper bushing --- topside with

pulley off - I dribbled a few drips of 20 wt. turbine oil down in

between shaft and bush . It takes a little time to soak in. The fresh

oil seemed to help a little. But with the power on the motor ran with a

loud rattle complete with a rhythmic knock. The kind of knock that

sounds off with every rev. This motor was terminal, I thought. Pretty

sure there's crash/crunch damage in the area of the thrust.

*

Something in there is chipped, fractured, broken. Can't see it. It

appears to me impossible to gain access to the rotor assembly.. The

motor casework won't come apart without destruction. Not designed to

disassemble. Not that I can see at this point. However you can get lube

where it needs to go.

With the end cover removed from the motor

case there is an open passage that leads to the inner bushing and

thrust. It's the open gap around the commutator. However a large

diameter flange (item #6 in the cutaway dwg above) that locates the

thrust also blocks the view when looking at it with the cover off. But

the oil pours in and finds the bushing and thrust, The chamber will hold

a fair amount of lube. I saw nothing to lose and proceeded to flood it

with 20 wt. turbine oil. Put the end cap back on, reassembled the motor

to the pod complete with capacitor soldered across the terminals. After

that the rotor spun lots quieter between thumb and forefinger. The shaft

felt lots firmer in its bushings. No more rattle. There is a pretty big

difference between dry and lubed up. Did I mention I used 20 wt. turbine

oil?

* brush end. Where to pour the oil in. Note also how the brushes operate

coated with grease.

brush end. Where to pour the oil in. Note also how the brushes operate

coated with grease.

(hint: click on thumbnail to view image full size)

After getting lube to the inner bushing and thrust the motor ran strong when powered up. And then, with pulley and drive belt assembled, and the turntable all set up and ready, the motor in its pod spun the platter with normal ease. That part of the story is good. And the controller worked properly. Pretty much like a belt driven Teres should except for.....the knock-knock was still there, much lower in noise level. Softer knocks. But still going knock-knock. Stand away from it 5 feet and you might not notice it.

* Driving the lead shot-loaded platter.

Driving the lead shot-loaded platter.

Yet, even if' you've got music playing, the tick - tick still

intrudes upon the experience. So the next thing was to find a

replacement motor, another older A-max 110189 that doesn't knock

perhaps. If you know of one I know someone who would like to buy it!

Anyway this page is to inform about getting lube into the bushings

and thrust The idea being to get lube where it needs to go before there

is any permanent damage like this one has. Keep it lubed and the brushes

should last quite a while before finally wearing through.

* (click thumbnail for full size image)

(click thumbnail for full size image)

*

Above: Data sheets published by Maxon

*

*Below: some shots of my old Teres Signature 2 motor pod with its older A-max 110189 in various states of disassembly.

*

(click thumbnail for full size image)