-edible zone-

-- On the way toward getting some better sounds out of a TD126 mk3

-- Photo 1)

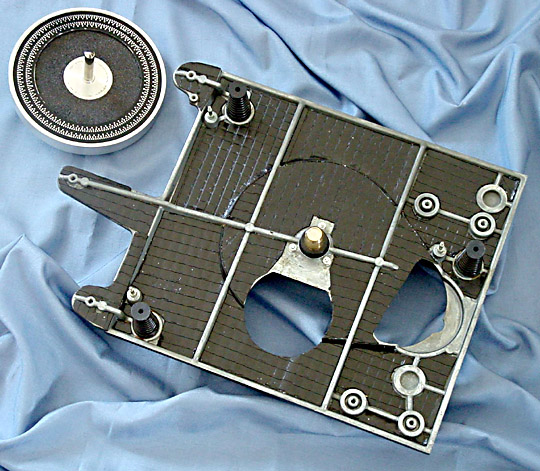

--# Above photo 1: TD126 mk3 subchassis assembly -----with some mods.

--Photo 1a)

photo 1b)

photo 1b)

(click thumbnail for full image)

(click thumbnail for full image)

--#Above photos 1a and 1b: For comparison....a TD125 mk2 sub-chassis with bearing. Above photos 1c and 1d: a TD125 mk1 sub-chassis with bearing. Note the 3-screw configuration of the mk 1 whereas the mk2 is pressed in and has no retaining screws. Later mk1's also used the press-fit bearing.

-- Photo 2)

-- Above photo 2: Underside of sub-chassis shows damping material

applied. The Thorens TD126 mk3 sub-platter is replaced by the above

Thorens Ambiance sub-platter with RDC damping material applied. Bearing

shaft is standard 10mm and with the traditional Thorens conical tip. The

standard TD126 mk3 strobe ring is installed to this sub-platter.

Q&A session:

Question: "There appears to be damping material

applied to the bottom side of the cast aluminum sub-chassis plate. Is

this the same material you used in the construction of the Reference II.

Looks like the stuff. How much weight does this add..?"

Answer:

"It is a resonance damping foil normally used to calm sheet materials in

cars etc. It comes from a company called " Teroson " and it is very

useful."

Question: "Do I also see damping material in the

underside of the sub-platter...? This appears different from the damping

material used on the sub-chassis plate. Is it applied by Clearlight or

yourself...?

Answer: "The platter is an original Ambiance

platter. It is a massive aluminum part, filled with RDC material ( like

the 2001 Iso-track platter as well ) by clearlight.

Question:

"What about the sub-platter itself..? This is an Ambiance sub-platter

manufactured by Clearlight...? It has some different features from the

standard TD12x/16x sub-platter. Looks like it is turned from a solid

billet of aluminum."

Answer: "Yes, You are right, but Clearlight

did only the RDC filling, all parts are Thorens constructions."

Question: "I also see the familiar 10mm shaft with conical tip." "No

captive ball bearing as with the TD150 and early TD125's..?"

Answer: "It is an original aluminum sub-platter with the 10mm 2001

shaft."

Question: "The strobe ring is a standard TD126 unit...?

Will the Standard Thorens TD126 mk3 speed control circuitry be used...?"

Answer: "In the moment I use the original motor drive and speed

control of the TD 126. My goal is to develop a quartz controlled motor

drive, using a synchronous AC Motor like the TD 520. This drive should

be also a high quality replacement kit for all turntables, whose motors

are available no more."

--#Photo 2a)

(click thumbnail for full image)

(click thumbnail for full image)

-- Above photo 2a: For comparison a standard TD125 mk2 sub-platter. These are die-cast zinc with minimal machining in key areas. A closer view around the perimeter of the strobe disc shows staking to hold this piece in place.

-- Photo 3)

--#Above photo 3: Top view

-- Photo 4)

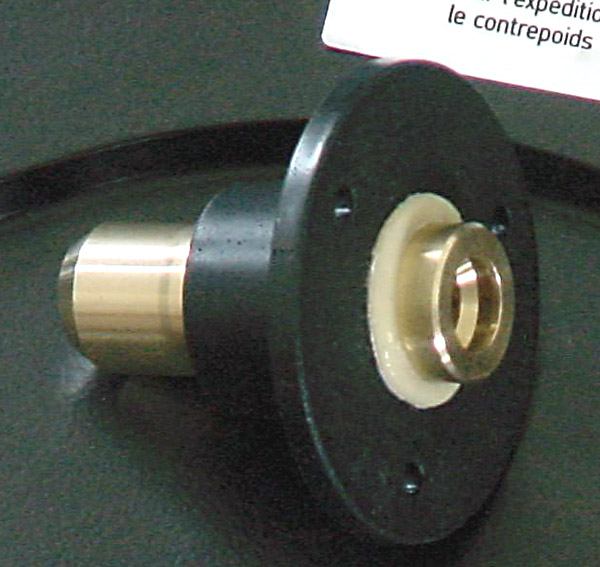

-- Above photo 4: View of the Ambiance/RDC bearing. Three machine screws secure the bearing

-- Photo 4a) .

-- Above photo 4a: Close up view of the Ambiance bearing.

--

Rolf's notes on the RDC/Ambiance bearing. "The 10mm main bearing sleeve

is a former Thorens construction made of brass, used in many players

like TD 320, concrete, 520, 2001, 3001 and Ambiance. But only the

2001,3001 and Ambiance are using mirror polished widia steel ground

plates. These plates have 10 mm diameter and were pressed into the

bottom of the sleeve. We have hundreds of these expensive plates in

stock" (see photo 5)

"Thorens used aluminum mounting collars for

the standard versions of 2001 and 3001 or pressed the bearing direct

into the chassis (520). Clearlight took a casting of the aluminum collar

and reproduced it in RDC material developed by Kurt Olbert. Bearing and

collar of the RDC construction are sealed together."

Question:

"There appears to be a yellowish white ring shaped material around the

boss at the top side of the bearing. Making it a three piece affair.

Washer or sealant..?"

Answer: "Using the described parts, I have

to fit them together in a position different to the Ambiance position,

because Ambiance and TD 126 have different chassis geometries. So I

formed an adhesive material ring to fix the correct position of the

parts."

--Photo 5)

-- Above photo 5: Widia ground plate as used in Ambiance/2001 bearing

as well as in Rolf's 126 upgrade bearing.

The following

parts are used:

10 mm spindle ( TD 2001 )

10 mm widia

bearing ( TD 2001 )

RDC bearing flange ( Clearlight Audio )

RDC driving platter ( Ambiance )

strobo ring ( TD 126 )