-edible zone-

Inspection:

Above photo: checking the old bushing for wear in its precision bore. The gage has been set to read zero at .1875 inches. The technique is to measure in several areas of the bore to gather an overall impression of the condition. In the photo the reading indicates size to be .1879 inches. That was taken toward the upper end of the bore. At the lower end the size read .1882. Roundness was ok with no obvious variation.

The motor shaft outside diameter measures .1869 inches. Running clearance will be .001 - .0013 inches between the old bushing and shaft.A bit large on clearance.

* (note: these bushings have been sold out. Nowadays you can find

replacement motor bushings from a variety of sources.)

(note: these bushings have been sold out. Nowadays you can find

replacement motor bushings from a variety of sources.)

* Above photo foreground: The pair of old motor bushings. Background.

The new ones.

At that moment in time, (2007) it was virtually

impossible to source new bushings for the E-50 motor.......unless you

had some manufactured. That is what was done. I contracted with a local

toolmaker to cnc some new replacement bushings for the E50 motor.

Material for the new bushings was Oilite bronze, SAE 841. The material

in the old bushings was, well, old.

* (click thumbnail for full size image)

(click thumbnail for full size image)

Checking size on the newly manufactured bushing. Reading is .1876 at every area within the bore. That is what I wanted. Running clearance will be .0007 inches between motor shaft and new bushing bores. Ready for another 50 years use.

*

Nex bushing concentricity check: id to od. Read was less than .0005"

runout.

Nex bushing concentricity check: id to od. Read was less than .0005"

runout.

___________________________________________________horizontal rule

*Assembly

* Upper cover: The oem mounting post was secured by a solid rivent. To

replace it the rivet end is drilled out so we can use the new double

grommet post which will secured via hex bolt.

Upper cover: The oem mounting post was secured by a solid rivent. To

replace it the rivet end is drilled out so we can use the new double

grommet post which will secured via hex bolt.

* >ower cover: Cleandd and ready.

>ower cover: Cleandd and ready.

* Lower cover: Detail view of the spherical socket.

Lower cover: Detail view of the spherical socket.

* Lower cover: New bushing spherical end fits into the spherical socket of

the lower cover. To assist the self alignment process, a small amount of

high pressure grease is added to the joint. The bushing itself has been

impregnated with "Thorens Oil" by placing the bushings in a small tin

can, submerging them in the lube and baking them at 250 F for a few

hours.

Lower cover: New bushing spherical end fits into the spherical socket of

the lower cover. To assist the self alignment process, a small amount of

high pressure grease is added to the joint. The bushing itself has been

impregnated with "Thorens Oil" by placing the bushings in a small tin

can, submerging them in the lube and baking them at 250 F for a few

hours.

* Lower cover: Oil retaining felt washer is placed around the bushing. The

felt has been soaked in 20 wt turbine oil. (Oil spec: Texaco Regal R&O

46) The oil is only sold in 5 gallon and larger containers. I should

have a lifetime supply...;-)

Lower cover: Oil retaining felt washer is placed around the bushing. The

felt has been soaked in 20 wt turbine oil. (Oil spec: Texaco Regal R&O

46) The oil is only sold in 5 gallon and larger containers. I should

have a lifetime supply...;-)

* Lower cover: The retaining cap holds another felt washer (also soaked in

Thorens oil)

Lower cover: The retaining cap holds another felt washer (also soaked in

Thorens oil)

* Lower cover: The retaining cap with retainer clip designed to fit the

spherical end of the bushing.

Lower cover: The retaining cap with retainer clip designed to fit the

spherical end of the bushing.

* Lower cover: The retaining cap in position.

Lower cover: The retaining cap in position.

* Lower cover: A new thrust pad (Delrin) is cut to replace the old heavily

indented original nylon pad. A slight amount of grease allows the pad to

stick into position as an assembly aid. Fasteners are M2.5 x .5mm

slotted cheese head screws and hex nuts.

Lower cover: A new thrust pad (Delrin) is cut to replace the old heavily

indented original nylon pad. A slight amount of grease allows the pad to

stick into position as an assembly aid. Fasteners are M2.5 x .5mm

slotted cheese head screws and hex nuts.

* Lower cover: With bearing assembly fitted.

Lower cover: With bearing assembly fitted.

* Lower cover: Detail of the assembled thrust cap.

Lower cover: Detail of the assembled thrust cap.

__________________________________________________________________horizontal rule

Putting the motor together: This assembly requires an alignment between both upper and lower case halves to be concentric to the motor shaft. Closely concentric so that the rotating part spins freely. And it won't unless we do.

*Text below is most recent update to my E50 assembly process.

After fastening the bearing assembly onto the lower case. The inner

cap tensions the bushing while allowing the bushing to swivel a small

amount within its spherical socket fitting. The m2.5 hex jam nuts were

carefully ,and somewhat tediously, fitted with my fingers to engage the

threads of the machine screws. Once the nuts had a 'start' on the

threads I used a screw driver to engage the slotted end of the screw

while holding the hex nut with a small plier. In this way I was able to

tighten the assembled bushing quite firmly to its end case. Do note that

the spherical end of the bushing must not be locked into position. It

must be able to swivel within its assembly. Test this by placing the

rotor shaft in the bushing and manipulate the bushing attitude using the

leverage of the rotor shaft. If the bushing puts up too much resistance

there is something within the assembly that is wrong.

The

bushing assembly is installed to the upper

case the same as the lower but with the exception that there is

no end cap. The rotor shaft fits through the upper case. Like the lower

case, it is important to insure that the upper bushing can be easily

swiveled within its spherical mount.

The importance of the swivel

mountings is for aligning the rotor shaft to the bushings. Ideally, upon

assembly, the rotor will spin within the upper and lower bushings only

touching a film of oil and not making hard contact with any part of the

bushings themselves.

* Don't forget about that thrust ball at the bottom thrust. It's 2mm

in diameter and might go unnoticed unless you're looking for it.

So we do. Hold it in the socket with a small dab of bearing grease.

Don't forget about that thrust ball at the bottom thrust. It's 2mm

in diameter and might go unnoticed unless you're looking for it.

So we do. Hold it in the socket with a small dab of bearing grease.

*Before installing the motor to the chassis. And before applying

electricity to the motor. With the four assembly bolts not yet

tightened, slightly loose. Hold the motor in one hand. With the other

hand hold the top of the rotor shaft between thumb and forefinger.

Wiggle the shaft back and forth, around and forth, to operate the self

aligning bushings within the upper and lower casings in an operation

designed to align bushings upper and lower to the rotor shaft. Then,

spin the rotor shaft by giving a spin with the thumb/forefinger hand.

Observe how long the rotor spins. Repeat this process until the longest

spin-down time is achieved. Tighten the four bolts, then double check

the spin-down time. If longest spin-down time is achieved after

tightening the four bolts, you've got it.

editors note: It has

been my experience, after a few years of working on different TD124

players and seeing the variety of conditions that these motors may be

found to be in, I have revised my technique for final assembly as

follows.....

Noted above in the paragraph prior to this note, it

is in the hand-held assembly stage where the most effective method of

shaft centering can happen. When the upper and lower case bushings are

best aligned, there will be the longest spin-down time. When in good

alignment the rotor will free-spin for several seconds before coming to

a gradual halt.

- Some factors that affect free-spin times.

- Alignment between upper case bushing and lower case bushing. The apparent need for the two bushings to share same exact center-line with the shaft.

- Bushing wall to rotor-shaft operating clearances. This involves the diameter of the bushing compared to the diameter of the rotor shaft. The clearance between these two diameters must be held to a useful working tolerance. Tighter shaft/wall clearance results in shorter free spin. Greater shaft/wall clearance results in longer free-spin times due to less drag

- Lube viscosity. Greater viscosity (thicker) lube will produce higher amounts of drag against the rotor shaft and, all other things being equal, you get shorter free-spin. The opposite is to be expected for less viscous lube given no change in bushing wall to shaft working clearance..

- Rotor bearing thrust must be in good repair. A fresh thrust pad is always a good idea when restoring one of these E50 motors.

_________________________________________________________________horizontal rule

* Assembled motor: This view shows the new Double Grommet posts installed

to the upper cover. The grommets and posts were sourced from Mirko

Djordjevic out of Huntington Beach, CA. Mirko manufacturers and / or

sources many oem parts for old Thorens, Garrard and Lenco turntables.

Quality of workmanship, as I've seen so far, looks very good. Prices are

reasonable.

Assembled motor: This view shows the new Double Grommet posts installed

to the upper cover. The grommets and posts were sourced from Mirko

Djordjevic out of Huntington Beach, CA. Mirko manufacturers and / or

sources many oem parts for old Thorens, Garrard and Lenco turntables.

Quality of workmanship, as I've seen so far, looks very good. Prices are

reasonable.

* Fitting the grommets into the chassis.

Fitting the grommets into the chassis.

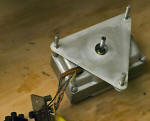

* Assembled E-50 motor with shield and ready to fit into the chassis

Assembled E-50 motor with shield and ready to fit into the chassis

* View from above: Assembled motor.

View from above: Assembled motor.

* Close-up detail of the double grommet configuration.

Close-up detail of the double grommet configuration.

*

Last two photos: The electrical hook-ups.

Last two photos: The electrical hook-ups.

*Next: E50 Stator Coils