-edible zone-

Thorens TD160 mkII S/N : 270127

(click thumbnail for full size image)

(click thumbnail for full size image)

S/N : 270127 This unit was exported to, and sold in Canada.

Years of production : 1976 - 1984

Some notable details:

Safety post is present

Detail changes to TP16 arm from MK I

configuration

Detail changes to dustcover in the way it hinges in

back, and now rests on top of the plinth in front.

See the cutout

in rear of dustcover. To clear lateral float of the platter?

Hardwood veneer over particle board of the MK I is changed to sheet

metal sheathing over particle board for this particular unit. More

details about the plinth shown in inside views.

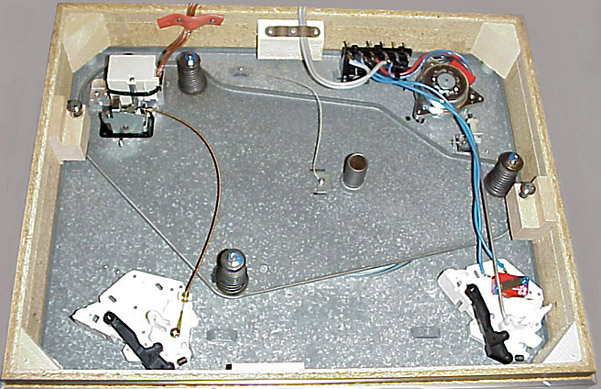

Underneath layout is fundamentally the same as MK I with some detail

changes.

1) The phono output fixture has been relocated to

directly under the armboard on this unit.

2) Wire clamps for 115

input and phono out appear changed from MK I configuration

3)

Plinth has no veneer inside or out. Appears to be constructed from more

than one piece. Overall, this plinth appears slightly lighter than the

MK I.

Other details will be noted in close-up photos below.

(click thumbnail for full size image)

(click thumbnail for full size image)

Above: Subplatter views and the safety clip

Above: mk2 spring assembly appears unchanged from MK I. Same rubber grommets upper and lower. Same spring, flat washer and hex nut. Stud configuration is unchanged. Note two colors of foam inside the spring. The upper light brown foam would be factory. The lower black foam will have been added by a second or third party. The service sticker on the back of the plinth is probably a clue to who did the foam addition. Bounce seems free in the vertical and horizontal but shows good resistance to foot-fall disturbance on suspended floors. I've personally tested this. But....it is against current popular thought that the inner foam should be eliminated. The thinking being that the foam can make a path between the steel stud that holds it and the subchassis, via the foam. These days I don't use any foam. Rather I'm careful to park it on a structure free from footfall.

The mk 2 layout remains unchanged in the configuration from the MK I,

but with some minor detail and cosmetic variation. The acrylic dustcover

now has an altered hinge configuration. The dustcover now rests on top

of the plinth in front. The MK I had a aluminum shelf for the dustcover

to rest on and featured hinge pins to the side. The tone-arm rest shows

a different look. The tone-arm itself has undergone a major change and

will be covered in more detail on the MK2 TP16 page. The top facia has a

slightly different pattern. Hardwood veneer has been exchanged for

sheet-metal sheathing on this model.

The plastic block in front

of the TP16 in this photo is an optional gadget called a "Thorens Q-UP",

who's function is to lift the tone-arm up off the record when end of

play has been reached. More about this device in it's own section.

________________________horizontal rule

TP16 mk 2

Above: compared to the MK I, the most apparent change in the MK 2

TP16 tone-arm would have to be the

TP-62 "ISOTRACK Plug-In-Arm

Wand",

which replaces the TP60 plug-in-head shell of the MK I. The arm rest for

the TP-62

is changed from the MK I arm rest to accommodate the

different design.

(click thumbnail for full size image)

(click thumbnail for full size image)

Above: The open end feature of the TP-62 makes one wonder if

the design handles resonations differently

from MK I design? It

would appear so.

Changes at this end of the TP16 are less obvious. Note the missing

threaded end-cover-plug out back?

Also, there are no jam nuts on

the horizontal gimbal bearings as on the MK I. Perhaps what is seen

would be a cover

that needs removal so that access may be gained

to the bearings..? Special tool required. VTF and Anti-skate

adjustment appear to function as before. Azimuth and VTA setup require a

special fixture supplied with the table.

Cueing remains the

same.