-edible zone-

Q: What is a Teres...?

A: look below.....!

It is

sold as a kit, and some assembly is required.

Date: 5/01/02

*

Here's the breakdown:

The Standard Kit:

Teres Model

135 Acrylic Kit minus tonearm, comes with motor pod, power supply and a

two piece screw-down record clamp.

Options:

Expressimo

Audio modified RB 250 tonearm w/VTA adjuster

Black Diamond Racing

resin cone feet

For more info surf over to this link:

https://www.teresaudio.com/

'Ya-think they put enough acrylic in

it...?

Assembly and polishing, how it went.

Even though

this is termed as a "Do-it-yourself" kit, there isn't much for the

purchaser to do except for polishing the acrylic and then some very

simple assembly. I did the whole thing in the kitchen of my apartment.

Actually I have a garage workshop, but I found working in the kitchen

sink to be more convenient for the wet sanding process. Running water.

The platter comes finished and ready for assembly, but the base and

armboard are in 'as machined' condition. The polishing process is

similar to the color sanding operation used in custom show quality

automotive painting. The surface is sanded with a succession of finer

grit papers followed by a fine polishing compound. After the compound,

the acrylic takes on the look of transparent cut crystal. It's

satisfying to do this work and see the material transform under your own

hands and before your own eyes. It's easy too.

Here is my

approach to the sanding process:

6 inch sanding board.

(pro-quality, purchased at an automotive paint supply store, years ago)

120 grit dry sandpaper

220 grit wet

400 grit wet

600 grit wet

1200 grit wet

3M heavy duty polishing

compound (bought in an automotive paint supply store years ago)

McGuires #5 Mirror Glaze

The process goes like this:

Rough

cut with the 120 dry on the sanding board to cut below all machining

tool marks.

Wet sand with the 220 thru 1200 grits in succession.

It's important not to skip or go lightly at any of these levels as the

finer grit papers just wont cut below coarse sanding marks. I used the

kitchen sink for this wet sanding. With the rubber base of the dish rack

angled against one side of the sink and a heavy sponge for the platter

base to rest on as I did my sanding. This worked well and made very

little mess. All the dust went down the drain. By the time I was at the

1200 grit level, the acrylic was quite transparent when wet and a bit

cloudy when dry. The 3M compound polished the plastic clear and the

McGuires #5 put a finish shine on it.

Assembly:

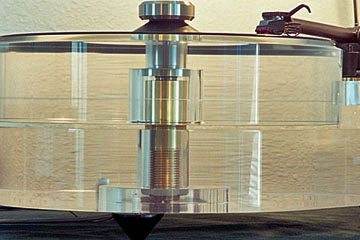

1) The

bearing drop. The spindle and bearing housing undergo an interesting

process of assembly. Due to a close tolerance of fit between spindle and

bearing housing, a structured process of assembly is used. The supplied

instructions were adequately clear so there is no need to improve on

them here.

I'll just say the following: The spindle bearing is a

nice bit of machined hardware. The housing is solid bronze, the spindle

is stainless steel. There is a precision ball bearing that rides between

the spindle bottom and a teflon coated thrust plate in the bearing

housing. The whole assembly is submerged in oil. Installing the spindle

into the housing took over 12 hours to accomplish due to the close

tolerance fit between spindle and bearing in combination with the oil

loaded into the housing sump prior to assembly. The spindle drops easily

down to the pool of oil in the sump. There the spindle stops solidly

with no cushion. Brick wall. Then the platter is installed over the

spindle to add weight and push the spindle on it's way down to the

housing bottom. Over time oil is displaced up past the microscopic gap

between spindle and bearing and thus allows the spindle to make it's way

down to the bottom allowing the ball bearing to ride solidly against the

thrust plate. Once the spindle is fully home, there is visible oil

clinging between spindle and housing at the top. This can be seen

through the acrylic platter. It looks as though the spindle rides in an

oil-bath vacuum. Neat.

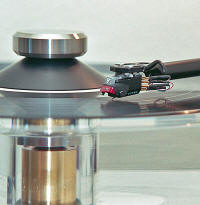

2) Arm board and tonearm. Straight forward

stuff here to anyone who has ever aligned a cartridge except that the

pivot to spindle distance must also be set. This is simple as the arm

board is secured to the plinth by a single bolt. Loosening that bolt

allows the arm board to swing into position. I took advantage of the

Clearaudio protractor I have to set the spindle to pivot distance,

stylus overhang and offset angle. Piece of cake.

The Expressimo

RB 250 'modified' tonearm:

*

The difference between this tonearm and the 'standard issue' Rega RB

250 is that Expressimo has exchanged the plastic counterweight

stub-shaft at the end for a stainless steel one. Expressimo has also

manufactured an offset counterweight that locates the center of it's

mass approximately at stylus level for improved tracking. Another

improvement on this arm is an upgrade Cardas wire set.

The

cartridge clips are springy and snap over the posts locking into final

position.

(click thumbnail for full size image)

(click thumbnail for full size image)

Above: close-up view of

Cardas clips plugging into the Shure

BTW, the buzz on the RB250

is that when modified as above, it becomes superior to it's more

expensive siblings in the Rega product line. The difference being that

the more expensive Rega arms employ a Vertical Tracking Force adjustment

mechanism. This device has just enough 'ring' to it to add a resonance

of it's own to the arm and subtract a tiny bit from the pick-up signal.

The '250 has no such VTF adjuster and therefore does not have this

problem. The cheap arm wins. How nice for us, the teaming masses. Power

to the people.

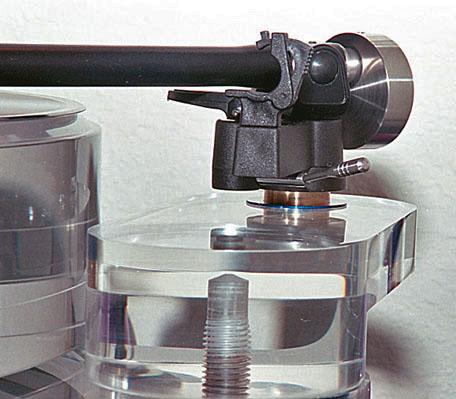

VTF (vertical tracking force) adjustment is

accomplished by sliding the counterweight into position on the end stub

and then tightening an Allen set screw. Not elegant, but effective. Of

course, you'll need a scale to set tracking force with this rig. Then

again, a scale should be used with all arms so it's really a non-issue.

VTA (vertical tracking angle) adjustment is accomplished with

another Expressimo manufactured device. It is a simple threaded collar

that screws on to the threaded barrel of the tonearm. Fitting between

the tone arm and the arm board, VTA is adjusted by turning the collar.

It seems easy, and is, however this can't be accomplished without

removing the tonearm from the arm board. Fortunately, this is not

difficult to do with the Teres as the arm board is pretty much hanging

out in the breeze, allowing full access underneath to the tonearm

retaining nut. It is recommended that the retaining nut be torqued to

just beyond 'finger tight'. A light touch is required.

Pivot to

spindle, effective length, overhang and offset angle were set with a

Clearaudio alignment protractor.

Above: view of VTA adjuster and off-center"heavy weight")

Cartridge:

I chose to use the Shure V15VxMR I've been using on my

Thorens. This cartridge has 6 mos. use on it and as such is just nicely

broken in. It also makes it convenient to make a comparison in sound

between the new Teres and the old Thorens. More about that later. The

Shure mounted easily to the RB 250 arm and aligned with no fuss. This

may not be the ultimate cartridge to use on the RB250, but it tracks

well and offers great sound for it's price point. It has a stylus guard

too...!

Motor and Drive 'String':

*

Above: drive motor pod with silk bead cord

Motor

arrangement. An infrared optical sensor installed to the acrylic

base reads a strobe grid on the platter bottom. The signal is regulated

by microprocessor with some circuitry designed by Manfred Huber and

built by the team at Teres. Nice work on this one I'd say. Operation is

straightforward. There is a pushbutton to start the motor. Push it for a

short moment and up comes 33-1/3 rpm. Hold the button down longer and

you get 45rpm. A red L.E.D. tells us the motor is still spooling up. A

flashing green L.E.D. let's us know it's getting close. When fully up to

speed, the red goes out and the green is constant. Should the rpm waver

for any reason, the red comes back on. I see this when I use the carbon

fiber brush at the start of play each time.

Another, very

pleasant way to operate this table is by simply giving the platter a

gentle push in the correct direction. The motor will start this way. You

can stop the platter simply by stopping it with your hands. I get a

certain satisfaction using the table this way.

Then there is

the drive string. Extended use suggests that drive pulley needs to

be closely parallel with the platter. If close parallelism is not

maintained, the silk string begins to ride against a corner of it's

pulley and the resulting increased drag is enough for the string to slip

on the pulley. This slippage will start a chain of events involving the

speed calibration circuitry in the controller that will lead to an

audible pitch variation (music slows down). I found this to be very

disturbing at first. Now that I understand it, I simply maintain good

parallel alignment between pulley and platter, and I hear no more of

this.

Test Record Time:

I use the HFNRR test record for

making final arm/cartridge adjustments. Here is the final test report

from that session:

Tonearm = Expressimo RB250

Cartridge =

Shure V15VxMR

Vertical Tracking Force. 1-1/8 gram set with Shure

SFG-2 scale.

Side 1

Track 1) Channel

orientation...............pass

Track 2)

Phasing..................................pass

Track 3)

Balance..................................pass

Track 4) Balance,

left...........................pass

Track 5) Balance,

right.........................pass

Track 6) Anti

Skate...............................pass

Track 7) Anti Skate,

higher..................pass

Track 8) Anti Skate, higher

still............Fail

(note, I used Track 8 to fine tune anti

skate resulting in a mild buzz right channel when Anti Skate was set at

15/16 g. The best result I could get for Track 8. This is my final Anti

Skate setting. It's also worth noting that my Thorens never got to this

level. It would simply fail at track 6. The Expressimo RB250 is

obviously a better tracker than the TP16 MK I of the Thorens. This,

using the same cartridge in both arms.

Track 9) Anti Skate, even

higher.........Fail, jumps out of track.

Side 2

Track 1)

Tracking...................................pass

Track 2) Lateral

arm resonance...........9hz, big wobble

Track 3) vertical arm

resonance...........12hz, little wobble

Track 4)

Tracking....................................pass

Track 5)

Cartridge align - azimuth.........pass

Track 6) Residual

background noise....quiet well beyond any listening level

Track

7) Tracking.....................................pass

Operation:

see Review of Teres 135

The Teres Record Clamp:

The record

clamp is a stainless/delrin 2-piece assembly and secures itself over the

record by engaging threads on the spindle center pin. Function is very

good. There is also a delrin spacer that fits under the record to assist

in giving clamping direction to the vinyl. In many cases clamping is so

good that the record shows visible evidence of a slight vacuum when

taking the record off the platter. I'm truly impressed with this.

*

The Teres Platter Mat:

Guess what...? There is no

platter mat with the Teres...!

RB 250 operation:

It looks

a little precarious having the cartridge 'hanging' out in space the way

it seems to. I find the cue device to function adequately for safe

operation of the arm. By leaving the cue lever in the 'up' position,

there is no worry about the stylus dropping below record level. The arm

drop is nicely damped by the cueing device and is accurate enough to

place the stylus anywhere one likes at will. This arm will be easy to

live with.

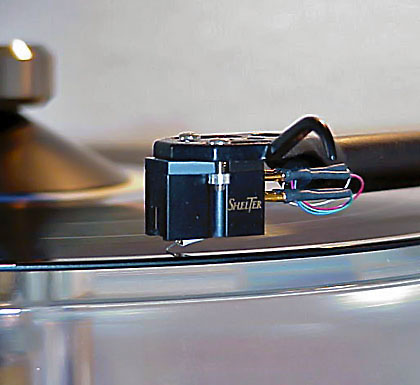

Date: 5/13/02,

New addition of a "Shelter

model 501 type 2" cartridge.

*

Date: 10/02, Signature Motor Controller Upgrade (see Teres 135

review)

Date: 11/02, Wright WPP100C Phono Preamp with MC Step-Up

Transformer (See review)

For a review of the Teres' sound

link here. Teres 135 Review