-edible zone-

Quote\ I looked forward to TRULY gorgeous results... the most difficult task is keeping "that" Garrard feeling, NOT going on unknown paths... like creating a new freak, a Frankenstein: not looking for obtaining a wannabe Micro or a Verdier, actually;-)! All must be carefully balanced and cared for... new, bespoke plinth, spindle, platter, mat, stainless-steel springs set, intermediate idler-wheel... like in a recipe for a great dish, difficulties and expense and effort must not over-shadow or make redundant the final result... ALL must "click" together and sound easy and effortless... and, possibly, better - I mean MUCH better - than a stock Garrard 301;-))) A Garrardzilla. /Unquote

The above words are those of the man who produced the subject of this

article. His name is Stefano Bertoncello. He lives in his native

Northern Italy. His online moniker is Twogoodears. (abbr:TGE) and he has

an audio blog of the same name. Here's a link: http://www.twogoodears.blogspot.com

Now we know why the name. To find out what Garrardzilla actually is

and how it came into existence continue reading.

It was not

without some small amount of surprise when I encountered a photo of it.

The first glimpse of that photo caused me a double-take. A Garrard 301.

That much was evident. It was mounted into a heavy plinth with a

separate stand-apart arm pod....both pieces were finished in an

automotive silver enamel. I've seen plinths with separate arm pods like

these often enough before. Always high mass. The arm on top of the pod I

hadn't seen before. Just looking, the effective length appears longer

than what is typically seen in the 12 inch category. And the platter. I

could identify its material as bare machined bronze. They certainly

didn't come that way originally. Lathe-turned bronze, taller than stock,

but of a diameter not much more than the original platter. The 301

aluminum chassis was finished in gray hammer-tone enamel and appeared

flawless. Perhaps the chassis had had a re-paint, …...or at least that

is what I thought.

Shindo came to mind. But the platter wasn't at all like anything I've

seen by Shindo.

Those were my thoughts until I started looking

for some facts. There was some text in accompaniment with the photo.

That text told me something of what I wanted to know, but not enough to

fully describe what it really and truly was that I was looking at.

I could certainly send TGE an email and just ask. Eventually I did.

But I knew about the audio blog. Maybe I'll just search through the

pages of his blog because he tends to document many of his projects

there, I thought. And my plan became 1: research the blog, then 2: ask

questions. And what I learned from the blog was quite a bit. In fact it

supplies enough information to fully describe this rig mechanically and

how it sounds to its owner's ear. Good info there.

Here's what I

dug up:

The cast alloy chassis isn't cast. It is cnc milled from

a solid block of aluminum by Ray Clark.

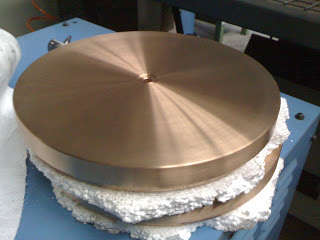

The bronze platter we see so

prominently on top weighs 29.7 lbs. (13.5Kg)

That blue platter mat up

topside is a Shindo 800 grams leaded cloth mat.

Under that platter is

a spindle bearing that looks like its been taking regular doses of

steroids

Stock motor with new stainless steel isolation springs

Slate plinth....massive slate, with stand-alone and also massive arm pod

Tonearm: It is "The Peak" heavy mass 16-inch and was chosen specifically

to work with a Japanese built Lumiere DST cartridge.

When I sent

an email asking my questions his reply indicated that this project was

A:a very personal search for musical satisfaction and B: Not a business.

All the better I thought.

From what can be seen of its exterior,

the above describes this beast in general terms. There is much more data

on this particular project player.

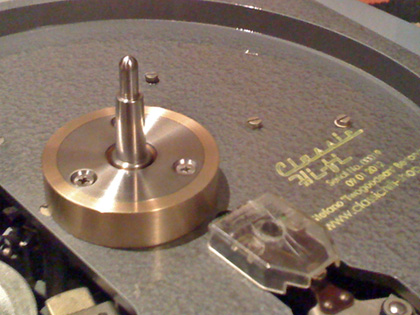

The

Bearing: Shindo, Commonwealth, Westrex 12D*, Garrard 301, EMT

930st. Those spindle bearings were studied in detail prior to arriving

at a design goal for this project. Classic Hi-Fi also produces a bearing

upgrade for the Garrards 301and 401. Yet the goal for this project

required a bearing suitable for supporting a load heavier than any

platter offered by Classic Hi-Fi or Shindo. So this is what was made:

Above: On the left is the Garrardzilla bearing housing and shaft. On the right is a stock Garrard spindle bearing standing upright next to the Garrardzilla bearing. The difference between them is apparent. That difference being “Length”. The Garrardzilla bearing is 40mm longer than the stock part. Additionally, the spindle pin is longer to compensate for taller/thicker platter mats and also to work with different record clamps that might be used. A very limited batch of this design was produced with intent that no more will be made. A local machinist was chosen to produce these.

Both housing and spindle shaft are stainless steel.

From

the blog: Quote/ ...my bearing uses a cool mix of exotic Kluber

(made in Austria) super expensive lithium/molybdenum grease and

compatible oil, making it a grease bearing design. This apparently

silly, small choice makes a world of difference in sound... the rotation

time-before-stopping decreased, but time isn't everything... the vibes

control and taming in EVERY sensitive area IS the goal! /Unquote

*footnote: re: bearings opened while design of the Garrardzilla

bearing was underway: TGE's comments about the 12D....Quote/ The

bearings opened, studied and measured included Commonwealth/Westrex 12D

- i.e. Commonwealth from Australia built the now sought after idler

wheel turntable under Westrex patent...My own 12D is now residing in

Berlin, in Thomas Schick's hands... after "things" are done, no need to

stuff shelves and shelves of unused gear;-) /Unquote.

An Idler Wheel

(hint:

click on thumbnail to view full size image)

(hint:

click on thumbnail to view full size image)

Above: custom machined idler wheel for Garrardzilla.

Material is

stainless steel.

Bushings are sintered bronze.

Rectified O-ring

wt: 250 grams.

The Platter:

Above: Custom platter in B19 bronze turned by a local machinist.

There were a few of these produced. And then no more.

Quote\ ….precision and being heavy duty enough to be used with the 13,5

kilos platter… using bronze isn't by chance… stainless-steel or brass

aren't giving same sound… I tried them and beside being cheaper and

beautiful, shiny, their vibration frequencies aren't the same… bronze is

darker, like live acoustic music is… and VERY dynamic and quick…/Unquote

Quote\ Every parameter of the several 301's strengths was

GREATLY improved: impressively dynamic and smooth, surprising at every

spinning... the added, improved mass and fly-wheel effect sure helps,

supports and improves the spinning stability, both mechanically and

aurally... the notes decay is of SELDOM heard beauty and quality...

looooooong and extremely various, with a world of ever changing

harmonics. As I leave platter running for hours and hours, never

stopping its running but if I have to change speed for some - rare - 45

rpm discs, when I finished my listening session I finally gave off to

the Garrardzilla;-) and, you won't believe... my hand light touch almost

wasn't able to stop the spinning platter... an enormous apparent weight

was felt by my fingers.../Unquote

One was coated heavily

with white enamel, while leaving the underside bare. The other was left

entirely bare. ( Editors note: 13.5 Kg is 29.7 lbs to us folks in North

America! ) For reference The original Garrard 301 cast aluminum platter

weighs 2.3Kg. The Classic Turntable Company's oversized bronze platter

weighs 10Kg. The Shindo machined aluminum platter weighs 6.7 Kg.

Garrardzilla: 13.5Kg.

TGE Quote\ Yes, the 13,5 kilos bronze

platter is the heaviest around... BUT the bronze and silky careful ultra

precise machining made THE difference vs. stainless steel and brass

platters... shiny, but sonically lesser... as materials and their

frequency resonances are paramount and weight alone isn't enough.

/Unquote

checking machined platter for runout. (hint: to view full sized photo

click on thumbnail)

checking machined platter for runout. (hint: to view full sized photo

click on thumbnail)

At one point there came a question; Does stressing the standard

Garrard 301 chassis with the additional weight of the bronze platter

(13.5Kg), and the more massive bearing designed for it, have a positive

or negative effect on the presentation being heard. His observations:

Quote/ The 12 kilos bronze platter used in the heavy duty,

super-smooth giant spindle/bearing both inserted in stock 301's

turntable add a brand-new feature to the whole: the added mass gives a

"seen" at chassis level "virtual mass" where the flimsy thickness of

original Garrard's alu alloy chassis get a stress due to

weight........snip..........At molecular level, the centered almost

five-times multiplied mass of new spindle and platter give about same

results than a turntable whose chassis weights 10/12 kilos with - maybe

- a better vibes taming character!........snip..............Having

access to a laboratory quality gears using, say, photoelastic stress

analysis techniques, all the above should be VERY visible and apparent

and clear.......snip.......The sound, are you asking?!?... don't know,

folks... the stressed structure of Garrardzilla sure gives "more" to

music... it's clearer, truer, it's... "is".... and this counts./Unquote

Ultimately this question and observations lead to Classic Turntable

Company for its 301 Solid chassis. This chassis offers greater rigidity

than the original lighter cast chassis and thus is able to handle the

greater loads encountered when using heavier platters and bearings.

Below: the CNC milled 301 chassis is offered by Classic Turntable

Company, Classic Hi-Fi Shop in the UK and its director, Ray Clark.

The next pair of photos (above) are the subject 301of this article.

The owners name and moniker, can be seen just below the serial number

and date of manufacture in the last photo, above right.

What makes these cnc milled chassis more stout and more rigid than the original cast chassis can be seen from underneath. Lacking in ribs and valleys, the overall thickness of the Classic Hi-Fi 301 Solid is uniform and holds much more metal while maintaining the same outer dimensional envelope as stock. This results in a more rigid and heavier frame.

(hint:

click on thumbnail to view image full size)

Above: underside of a Classic 301 solid milled chassis. (Photo taken at random from the net)

An

original chassis build for comparison.

An

original chassis build for comparison.

After the 301 mechanicals, (including Garrardzilla's oversized

bearing and platter), were installed into the Classic Solid 301 chassis

TGE gave his project a listen. What follows are his comments.

TGE Quote/ ... (speechless mode)...It's all and more I remembered and

missed for the last weeks, despite the truly superb Lenco's sonic

footprint... the original, stressed 301's chassis is doing well, BUT the

full optional Garrardzilla, including Ray's part and elegant, 401-like

underside screws is a completely different beast... still more dynamic,

with a resolution which only a bunch of us on the Planet experienced,

period. No hypes... The notes decay with every instrument, solo or in a

jazz quartet or trio is awesome... also if I only listened to three

records, this morning... Sidsel Endresen's on ECM with those crazy

shimmering cymbals and piano, Anthony Bailes' lute on EMI Reflexe for

tiniest resolution and ambient retrival and Ludwig Streicher double bass

and piano on Telefunken for explosive dynamics... all came soooo

naturally and beatiful and quick and beefy and undistorted! /Unquote

TGE Quote\ Ray Clark's Solid Chassis is a BIG part in Garrardzilla's

project... love its 401-style screws system, more elegant than stock

301's.... but the sound, THE SOUND is really awesome vs. stock

chassis!/Unquote

Tonearm

Choices

Looking at photos of the tonearm I made some visual assessments.

These 'impressions' ranged from: I haven't seen this arm before.....

and….It appears on the longer side of 12 inch effective

length........and.......it looks heavy..........and........no

anti-skate....and.......I wonder who made it, etc. Given that I was

coming up with all questions and no answers I asked TGE the following

question:

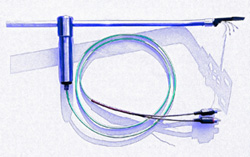

Q: (the analog dept) In my research of your project I

noticed some components I haven't seen before; 1) The Peak Heavyweight

tonearm and 2) the Lumiere DST cartridge. What I've learned about the

Lumiere DST is that it is a reincarnation (of sorts) of the Neumann DST

from many years past. The Lumiere has a similar coil configuration to

that of the NeumannDST but with an entirely different suspension design.

Its suspension design more closely resembles that of a mastering lathe

cutter. (take a look at JVC Cutter) I presume The Peak heavy arm became

necessary in order to make a better compliance match onto the Lumiere

DST and its ultra-stiff suspension, and to better handle what must be

significant spurious energy generated at the stylus-groove interface in

this configuration.

A: TGE Quote/ The Peak, with the "The"

it's sonically and to my ears, ahem... the peak in my arms stable,

period. Consider the arm was conceived by myself and hand-built by my

good friend and lathing & mechanic artist Mario, in Italy, painstakingly

auditioning different bearings, Abec 7 and 9 and arm wands materials -

i.e. two different thickness aluminium, titanium, stainless steel and

brass tubes... the contenders were FR 66-S, Ortofon RMG 309i, James

Grant's from New Zealand Cocobolo arm wand unipivot arm and Thomas

Schick's... all 12" designs with different should, from smooth,

forgiving, romantic sounding, to the quick responsiveness of the best...

The Peak arm uses Panzerholz/bronze rear weight with two decoupling

O-rings inside....this seldom seen solution has great sonic merits too.

The Peak surpassed all the contenders!

The cartridge of choice

remained the fussy Lumiere DST, the one and only to give me the

zestiness I need vs. my own and played real instruments and live music

experiences.

The Peak – thanks to its careful balance and

building care in sensitive areas, like the heavy mass headshell SME

screw-mount area - is able to play incredibly well, effortlessly and

with a sense of rightness, the heaviest dynamic grooves with a seldom

heard, if unique, aplomb... but without losing the finesse, the

detailing and introspective character I always loved sooooo much! The

Lumiere DST and its musicality - in use since 2005 - was completed when

I found an N.O.S. Neumann DST white cartridge which sounded REALLY great

despite its 50 years old vintage. /Unquote

TGE Quote\ The Peak

wires are 60 years old vintage Litz wire from headshell to phono

plugs...my good friend Lo who carefully made the twisting of the four

Litzes spent about two days of annoying twisting. Imagine twisting hairs

to obtain 130 cm (35 cm inside the wire and 95 cm outside it)....a

nightmare!! You need patience and a Zen-like attitude....Lo is the most

Zen guy I know! Avoiding a signal interrupting in the cable using Litz

of minute AWG is paramount. /Unquote

TGE Quote\ The

VTA base of The Peak is an original Fidelity Research B-60, as used in

my FR 66-S amd 64-S....having two and being that the above mentioned

arms are unused now....I'm using with the Peak....very cool Gizmo.

/Unquote

The FR B-60 vta base holds the Peak tonearm

The FR B-60 vta base holds the Peak tonearm

Above: a NOS Neumann DST (white)

fyi, vtf settings: Lumiere DST: ~3.5grams.....Neumann DST: 5 to

6grams.

The plinth comes in two pieces. A main base, (45 Kg) and

a separate arm pod (bronze, 25 Kg). The main base is solid slate coated

in Jaguar Silver Grey enamel. The armpod is lathe-turned bronze and also

coated in the Jaguar enamel. It stands its ground firmly planted by

means of its considerable mass......plus gravity ;-)

Standing on a dedicated steel stand for the turntable, the slate

plinth resides over another shelf of massive slate. The separate arm

pods are lathe turned from solid B19 bronze. Each pod weighs 25 kg (55

lb). Properly footed, these aren't going to move. The advantage is very

good mechanical isolation from the motor unit itself. With the separate

pod arrangement it is possible to have more than one arm in use with the

turntable simply by placing another pod with arm mounted in a suitable

location around the plinth. There just needs to be enough free area

about the turntable for the pod to stand.

Accessories.

For accessories we see it with a TT-weights Peripheral Ring (480 grams) and a 850 gram record weight produced by TGE. In the above photo we can't see which mat is in use so I asked which platter mat was favored and got a response indicating that the 'Blue' leaded cloth 800 gram platter mat from Shindo, a Suede mat from Jean Hiraga , A Micro Seiki 2.8kg CU-180 mat are used alternatingly, depending on mood. That seems about right with my experience. How many of us, myself included, swap out platter mats just to hear the difference in presentation!

Custom record clamp (TGE's design)

Custom record clamp (TGE's design)

Garrardzilla with Jean Hiraga Suede mat

Garrardzilla with Jean Hiraga Suede mat

(hint: click on thumbnail to view image full size)

Micro Seiki CU-180 mat on Garrardzilla.

Micro Seiki CU-180 mat on Garrardzilla.

re: The Peripheral Ring: In one blog post TGE reminisced how,

for a time, he had tired of using the peripheral ring due to the

repetitive efforts and ceremony involved in its use. And so the ring had

gone unused for a period...... long enough for dust to accumulate about

the peripheral ring at its assigned shelf space. Then the TTW peripheral

ring was put back into use. He says the difference in sound, that is

with ring -vs- without ring, had to do with an even lower noise floor,

improved dynamics, richer textures and improved sense of effortless and

liquid flow.

Conclusions:

Above photo: from behind the listening chair.

The three components that define it.

The three components that define it.

This ends the description of Garrardzilla and how it came into being.

(article continues below)

Please note that TGE has asked me to

state that duplicate parts made during this project have already been

sold and that no more are scheduled to be made again. And now I add the

following comments regarding where some of the 'prototype' parts went.

TGE Quote\ Thanks for pointing it out about the commercial

unavailability of these bespoke parts... yet, I'm very, VERY proud that

a handful of my prototypes are in use in very exotic audio systems of

friends who wished to follow my vision... all these gents owned The Very

Best gear available... and agreed (and still agree) about the uniqueness

of a Garrardzilla combo. /Unquote

Postscript: The

Garrardzilla project took place over a period of years dating from 2010.

Many intermediate steps, and also some of the parts designed, built,

tried and then not selected are not documented here. The intent has been

to describe the finished product and to include descriptions of some

parts that are worthy of mention.

Prior to beginning this project

TGE had been using both a Shindo platter with matching bearing, a Shindo

leaded cloth 800 gram mat After confirming the qualities of his

Garrardzilla bearing and bronze platter, he chose to sell the

aforementioned Shindo platter and its bearing. However the Shindo

platter mat was retained.

Shindo platter, bearing and lead cloth mat.

Shindo platter, bearing and lead cloth mat.

(hint: click on thumbnail to view full size photo)

TGE noted that the machined aluminum Shindo platter was delivered

painted on all surfaces, under and outer, and left with a slightly

uneven surface for the idler wheel to turn against. This is a detail TGE

gave consideration to, with the Garrardzilla B19 platter, and made

certain that a true spinning bare metal surface of very fine surface

roughness was present for the custom idler wheel to drive. A critical

area for any idler driven turntable.

One of the questions I asked

was whether or not any dedicated power supply or speed control

electronics were tried. His answer was that the stock Garrard motor and

pitch control have been retained and he notes further that the motor

seems well suited to the additional platter weight and sees no urgent

reason to pursue any electronic motor control.

The EMT 930st. In

the system pic. In the background is seen the EMT 930st standing within

its seismic base on the component stand against the back wall. It might

seem only logical to assume the superiority of the EMT over any other

turntable in the room. However TGE sees (and hears) it differently.

In a blog post from December, 2011 he states the following:

Quote\ Swapping tables, arms and cartridges dramatically made me

aware of the EMT's shortcomings... pleasant, smooth and "radiophonic",

in the sense it always reminds me when - I learned it after years - the

930st was "the" radio workhorse... its sound was... is no spikes, no

dips, let's say average sounding... a concept I already expressed

several times:-)

930st vs. 301 seems such a nice match... but

unfortunately (not for yours truly...) it's a true lesson for myself my

friends and everyone who doesn't believe that a table (and arm and

cartridge) owns a soul: the music flows freely and effortless, light to

the ears... never tiring... /Unquote

Other platter

materials:

The B19 bronze platter was the final result of much

testing. There were platters turned in stainless steel and aluminum. But

then Prior to the B19 platter there had been a custom platter lathe

turned from a rather large and expensive piece of Panzerholz multi-ply.

(hint: click on thumbnail to view full size photo)

(hint: click on thumbnail to view full size photo)

Above two photos: A Garrard 301 platter machined from Panzerholz. Outer surfaces coated heavily with enamel.

Stefano's comments on the sound using different platters from

different materials:

Quote\ …...used Delignits Panzerholze 330

mm disc (expensive!) Took to local machinist to have turned to Garrard

301 dimensions. With bronze insert at center to improve precision and

bearing matching. Painted outer surfaces. Inner surfaces, including the

inner rim that engages the idler wheel were left bare.” “Incredibly a 13

kg bronze platter sounds quite similar to a 3.5 kg Panzerholze platter

and both sound – you bet it – so different from original alu alloy

platter, which seems to lack – after direct comparison – that slam,

oomph and guts, and the greatly improved decay…. …The Delignit’s plywood

detailing is less exagerated vs. bronze’s very “severe” incredible

retrieval capabilities…. ,yet, acoustic instruments and classical string

quartets, acoustic guitars and voices are amazing with Panzerholz./Unquote

By now the reader knows that the B19 bronze platter was the final

choice. However the Panzerholz experiment is definitely interesting.

Others have used this material in platter construction. Favorable

comments seem to surround this material.

The intent of this

article has been to look into the original thinking and imagination

behind one very serious Garrard 301 project. As stated at the outset,

TGE's goal was to retain the essence of the original player while

extending its abilities to venture into qualities of playback its

original designer could not have imagined possible. And the goal was to

avoid turning itself into a thing that couldn't be identified by its

sound as anything other than a Garrard 301. To the ear, readily

identifiable and yet far better. This audio writer can only imagine that

it was successful on all accounts.