-edible zone-

-- The motor:

--

You can't get new replacements. Make sure the turntable you

buy has a motor in good condition. Check by removing the outer platter

and belt, then run the motor. It should run absolutely quiet. Only if

you put your ear directly next to the pulley will you hear only the

slightest whirring whisper. Anything more is excessive and unwanted.

If the motor makes a knocking noise, avoid it. Make sure the motor spins in the correct direction. Worn out or damaged motors will sometimes tend to run in either direction. Potentially, there is a capacitor at the AC mains terminal that can also be the cause of this fault. However testing will be needed to determine if the wrong spin direction is caused by a faulty cap or a tired motor.

-- Motor Shaft and Pulley.

Bent motor shafts are common on early TD160s. If you can't inspect the

turntable personally prior to the purchase, grill the seller about the

condition of the drive pulley. It should spin true and quiet.

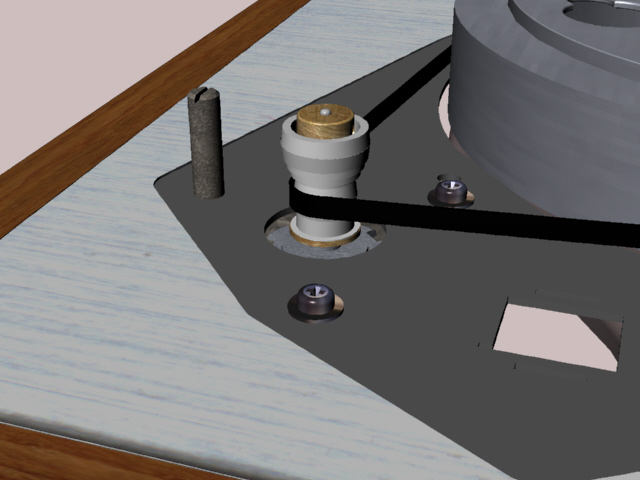

--Above 3D illustration: a detail view of the motor pulley, safety post and belt of a later TD160 Mk 1. The safety post replaces one of the three screws fastening the motor to the plinth. By virtue of its height, the safety post will take the hit from the heavy outer platter when it gets loose. Accidents did happen. Earlier models without this safety post often times have bent motor shafts and, consequently, drive pulleys that wobble when they should spin true. Look for this fault in any record player utilizing a 2 piece platter system, but especially in early TD160s.

--Platter Bearing.

The

condition of this key component will have a large influence over how

good the table sounds.

--

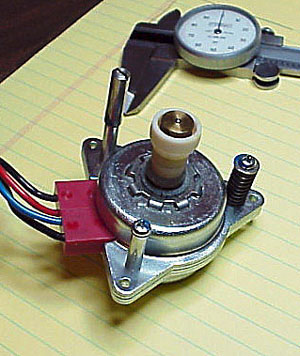

--Above photo: TD160 bearing shaft in very good condition. What to look for...? Wear patterns on the shaft where bushing contact is made. Expect to see 'more' wear evidence at the upper bushing than at the lower. Good condition can include visible signs of having been run in a bushing but with no grooving or wear pattern that can be felt by running ones fingernail across the area. A micrometer measurement should reveal no difference in diameter along the entire length of the shaft. The shaft should be perfectly straight.

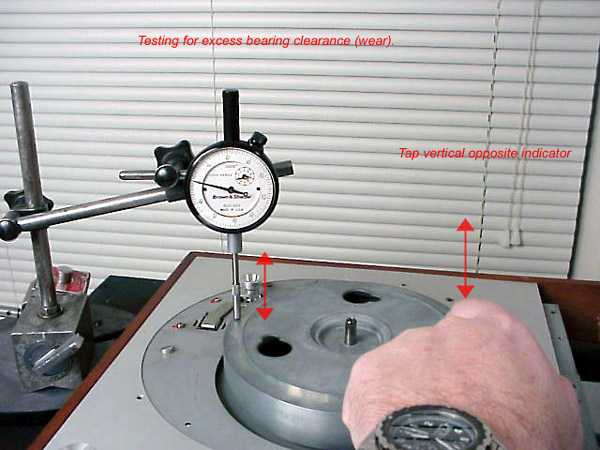

--# Testing the bearing for excessive wear.

--

-- With the bearing well full of clean lube, there should be no

perceivable indicator reading when testing as above. This particular

indicator can read down to .0005 inches. If the bearing well is dry when

this test is carried out, expect to see .001 inches of movement or

greater. That's normal for these Thorens players of the TD14x, 150 and

16x model ranges.

Ok, so you don't have the dial indicator. Carry

out the test as above but look for evidence of rocking or movement that

can be felt. Should be zero, none, nada, zilch.

--

-- Above: A platter bearing to a TD160 Mk II. This bearing was used on the TD135, TD150, TD125 Mk II, TD160 all marks and the TD145. Size is 10mm. For more info about Thorens bearings link here.

-- The bearing is comprised of two bronze bushings pressed into the steel housing. The flat thrust plate at the very bottom takes the entire vertical load of the platter system. This assembled weight is concentrated at the point of contact between the spherical tip on the shaft and the flat plate of the bearing. Prior to being put back into service, the interior of this bearing housing was cleaned spotless using a Q-tip saturated in alcohol. Oil filled the well half way up prior to assembling the shaft. When the bearing shaft is installed and finally floats down to the thrust plate, there is some small over-flow of oil out the top of the housing. This lets us know we have oil all the way up. As wanted. Thorens used a straight 20 wt. turbine oil on their platter bearings beginning with the TD124 its variants and the belt drive models that succeeded it. I do to. For a modern equivalent to the original 20wt. turbine oil there is an easily sourced direct replacement.

--

-- Manufactured by the 3-in-One corp. This is their more viscous straight 20 wt. oil designed for electric motors. Classed as a turbine / circulating oil. Not to be confused with their regular 3-In-One oil which is a much thinner viscosity light machine oil.