-edible zone-

No.6435

Overview Starting

Line Arrival Deconstruction

Beneath Decks

First Night's Spin

Listening to Plinths

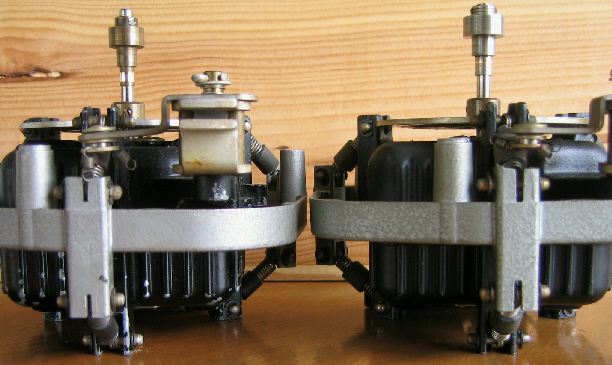

Motor

System:The Tonearm Tweaks

Articles

Bookshelf Transit

*

A few months into having an operational 301 I returned to the

condition of the drive-motor and it’s bearings. What is really simple to

grasp turns out to be relatively involved, if only in terms of access,

situated as it is directly at the center of the turntable mechanics.

The motor’s rotation is fixed on it’s axis at two points, an Upper

Bearing which serves as a guiding collar to steady the rotation, and a

Lower Bearing which not only steadies and centers the rotation, but also

serves to support the whole rotor-shaft as well.

Each is meant

to be well coated in electric-motor oil, and kept supplied with said oil

via an absorbent felt washer adjacent to the bearing assembly. When the

felt washer is saturated with lubricant it provides a reservoir with

which to keep the bearing and thrustball coated.

When I first

came to the motor bearings, I reasoned that since motor rotation felt

smooth before the lubrication, I could add some additional oil and call

it satisfactory. Well, partly true, but with a fifty year old mechanism

it’s all-around better to get in there and clear out the old lubricant,

start fresh with a squeaky-clean bearing that you’ll soak with brand new

lube….

If it’s the base for the motor’s rotational action, it’s

the basis of the turntable’s performance, so there’s every reason to be

sure that it is free of any oxidation or debris, and well packed with

lubricant.

So the next level is to get at the motor's lower

bearing and thrustball, for which you need to do the following :

1. with unit unplugged from power, set lever to Off and disengage

eddy-current brake via pitch control (ie rotating pitch all the way to

"+" moves the brake-shoe away from the eddy wheel & avoids damage when

deck is on it's back).

2. do not loosen upper motor bolts, do not

remove stepped motor pulley, or eddy-current disc from drive-shaft.

You'll be leaving all of that as set by Garrard.

Remove platter and

mat. Make sure you protect levers and spindle, and then turn the 301

upside down (use blocks, books, or the plinth to set table on it's

back.)

3. pull circlips off the three bottom spring-mount Pins,

and then disengage motor from bottom springs by pulling pins. 'Leaning'

motor toward the pin/mount you're removing lowers the spring tension and

eases the removal process, but don't over-stress other springs--- they

can be stretched too much. Also detach AC block from motor

4.

remove nuts from bottom-half 'clam-shell' casing of motor

5. in a

precise straight up motion remove bottom clamshell. Do nothing

'side-to-side' that could nick or graze motor shaft, or the softer part

#99, the Rotor Bearing, while sliding upward.

6. use a lintless

rag to "wick out" the bottom bearing. Clean with solvent like lighter

fluid the base of the rotor shaft, the interior of the clamshell, and

the bottom bearing / thrust-ball, which will benefit from a soak to

dissolve any hardened-up lube. Do not use anything that could deposit

lint or particulate into bearing.

7. wick out any remaining

fluid, solvent, lube and then fill bearing with a light motor oil. I use

the '3-in-1 SAE-20 special-blend-motor-oil', (not the lighter

‘household’ 3-in-1) for this, and also for the upper bearing. This also

benefits from an oil soak, a wick-out with a clean cloth, and a refill.

8. once complete, reassemble and turn table upright. Gently turn

motor manually for a minute or two to get bearing seated and smooth.

Start again if it is anything but smooth and freely rotating.

Sounds much harder to do than it is. These are the basics--- keep a

clean idler and platter-track, lube points cleaned and re-lubed. This is

the start you want to give any 301/401.

One easy alignment trick

is to run the table, at least 30 minutes on each speed, before

disassembling, so as to clear a bright polished mark on the steps of the

pulley. This will serve as an alignment key when setting the height

position of the rotor shaft after lower-bearing service, as below.......

Rethinking the bushing (#99) + thrustball (#120) + felt

washer (#100) + rivetted plate (#121) situation ... I really couldn’t be

sure that the thrustball was free and unencumbered.

I went back

yet again to the Garrard manual, which does in fact show, first, that

the thrustball is held in place by a concentric spring assembly (#98)

--and also, that those elements are on the outside of the aluminum

'clamshell' motor housing and thus pretty well contained for perpetuity

by the four micro-rivets that hold the cadmium-plated 1x1" cover,

(#121), onto the clamshell exterior.

They're outside of the motor’s clamshell housing.

So this little bearing setup is under lockdown unless you go to the

extent of drilling out the four tiny rivets and then retrofitting some

other fastener on reassembly......

Thus a good procedure is to

re-soak and hope to budge a reluctant thrustball, but again only with

something non-lethal to the finish of the bearing, washer, or ball...

Since I didn't think the elements were damaged, only slightly sticky, I

kept at it.

I was not inclined to add any heavy solvent /

penetrant, due to that felt washer, which I couldn’t be sure wouldn’t

dissolve entirely ----and so I went with a few more oil-soaks and

finally a Heated Soak. I just put the whole lower-clamshell-w/bearing on

the warm element of the kitchen range for an hour, topped up with the

bearing-assembly oil.

Another hurdle is that if you want any

'grip' on the thrustball as you prod it in hopes of turning it, you

can't use the same smooth slippery stuff (nylon stick, bamboo stick) I'd

been probing with. After the saute was over, I got another bamboo

kabob-stick and deliberately hacked it unevenly across, so the exposed

end was somewhat rough and mottled, so as to have some grip. I cleaned

up the cut a little with some light sandpaper, and, got rid of any

particulate .... and ... this was an all-around better ‘prod’.

And pretty much an immediate success. Whatever was left at the 'rear' of

the thrustpad, below the thrustball, just gave way. Just needed a little

more traction.

Guess I should emphasize that all I've done is

loosen up the thrustball ---- it doesn't come out of the rivetted

enclosure, by design. That would be a more elaborate strip-down, to

actually access the t-ball, bushing-shaft and felt washer.

I

waited for a complete cool-down, then replaced surplus heated-oil with

new clean oil and reassembled.....

Something I’ve learned to do

by now, with a couple 301’s getting lower-bearing service here, is to

Reassemble In An Upright Position. Which maintains all parts in vertical

relation to each other and allows the least spillage of the motor-oil.

It also slightly pressures that oil toward a complete saturation of the

felt washer before it exits upwards, which is the goal.

Giving

the motor-shaft a bit of gentle manual rotation during assembly also

helps seat the rotor in the lower bearing, which can be a little more,

or a little less time-consuming, depending on the original positioning

of the elements involved. Keeping up a smooth turning motion not only

helps the assembly process, but also serves as an early warning if

something is amiss with the fit.

It’s also well worth mentioning

that the final bolt tightness for the motor bolts should be done by

tightening in the turntable-upright position, and testing / inspecting

as you tighten. The vertical relationship of the parts on the

rotor-shaft (ie pulley, eddy-disc, etc) and their partners (idler-wheel,

brake-shoe, etc) changes slightly with bolts that are under or

over-tightened. What should be judged in the adjustment is, first, the

overall smoothness of the motor-shaft rotation, and second, the

positioning of the eddy-current disc, as viewed on edge, in the center

of the brake-shoe, which gives an idea of correct placement. If you have

run the table on each speed prior to disassembly, you can also use the

bright rings on the motor's stepped pulley to align to the idler. (This

works better on the 60hz brass pulley than the nickel 50hz one which

seems to keep a more intact finish.)

This takes a bit of trial

and error, but--- if the Upper Motor Bolts have never been loosened or

re-positioned, there is, at least, an existing starting mark for the

final adjustment of the Lower Bolts.

*

Parts Numbers here are from the 1956 ‘two-star’ Garrard 301 Schedule

1 Manual.

Thanks to Vinyl Engine for providing this online

version of the manual, applicable to the greasebearing tables.

Tweaks

Home